Introduction to the Computer System

Today’s vehicles have computers to monitor or control almost all of the vehicle’s systems. Many computer systems share information from common sensors.

Computers are interconnected via a data link called multiplexing. Some computers work together to control different aspects of the vehicle. Automatic traction control is part of the anti-lock braking system, but if the system detects a wheel slipping, it can communicate with the engine computer to reduce engine power and it can apply the brake to the spinning wheel. It can process this information and make decisions 5 to 100 times per second depending on the system.

The engine computer system called the Engine Control Module (ECM) or Powertrain Control Module (PCM) uses a variety of input sensors and switches for more information. The ECM’s processor uses the information to make decisions. The computer controls outputs like injectors, fans, solenoids, and relays to operate the various components.

An old saying about computers rings true for our vehicles today: “Garbage in, Garbage out”. If the information sent to the computer is faulty, the system will not operate correctly and will not function properly.

Automotive Computers

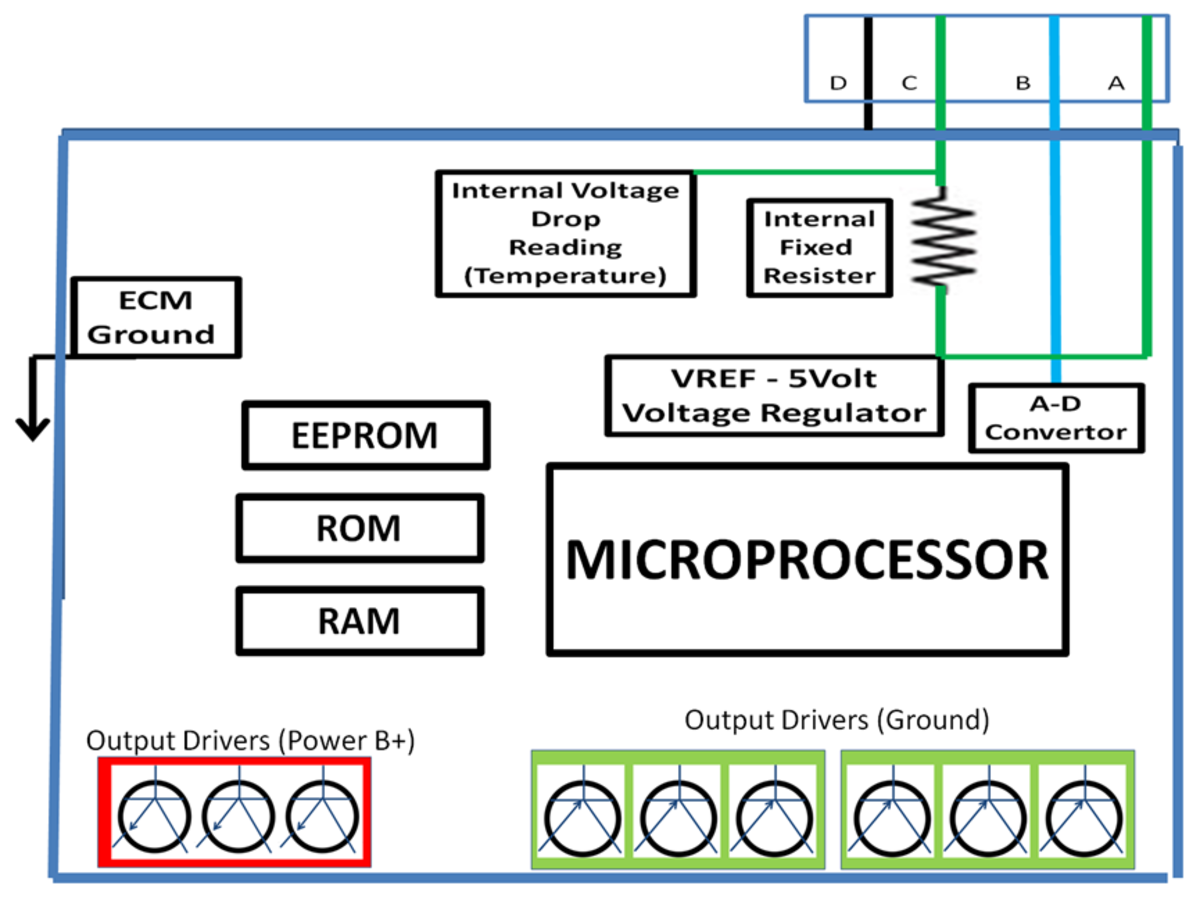

A computer is a processing and control device that has a variety of levels of complexity depending on the system it monitors or controls. Computers house a variety of components inside the infamous “black box”. The computer also has a built-in self-control system to monitor the system’s operation and will set and store fault or trouble codes. A computer can have several names depending on the manufacturer and what it controls. An engine computer may be called a; Engine Control Module (ECM), Powertrain Control Module (PCM), Engine Control Assembly (ECA), Motor Control Module (MCM), Body Control Module (BCM) or Electronic Control Unit (ECU). The main sections of the computer are the processor, memory, voltage regulators, analog-to-digital converters, signal conditioners, and output drivers.

Computer Memory

Memory falls into categories that reflect the volatility or erasure of memory. This also has to do with the importance of the information and whether it needs to be changed.

ROM (Read Only Memory) is memory that cannot be changed and is not lost if the battery is disconnected. This is where the basic operating system and other vital information are contained.

PROM (Programmable Read Only Memory) is memory that was factory installed and cannot be changed. The PROM was once a removable chip that had to be replaced if a change was to be made. Caterpillar called it a personality module that contained specific information about the engine and vehicle.

E-PROM (Erasable PROM) has the same information as a PROM but can be changed once or twice.

EE-PROM (Electronically Erasable PROM) has the same information as a PROM but can be changed repeatedly. Most vehicles today use EE-PROM as it can be reprogrammed an infinite number of times.

RAM (Random Access Memory) is the computer’s scratchpad, with this information constantly changing. Many vehicles today have the ability to “learn” driving styles, sensor minimums/maximums, and idle speeds. This information is retained until the computer stops operating or the batteries are disconnected. After a power loss, this information could be lost. On some occasions, the vehicle may run or idle “funny” until it “relearns”. KAM (Keep-Alive Memory) is another form of volatile memory.

Voltage Regulators

The computer operates on a lower voltage than the rest of the vehicle. Earlier in this article, we talked about 5 volt VREF. This is a 5 volt reference voltage sent to many sensors. This voltage must be very precise and stable; otherwise, the sensor readings would not be accurate. Some manufacturers allow a variance of 0.2 volt; others as small as 0.04 Volt. If for some reason the voltage regulators are faulty, you may have fault codes for several sensors due to the sensor voltage being cut off.

A to D Converters: Analog-to-Digital Converters

An “A to D” converter turns a constant voltage into digital numbers (pulses) or an alternating voltage into a DC digital signal. Computers are digital DC and do not understand anything else. The A to D converter is like a translator that translates signals the computer cannot understand into something it can use. The computer actually runs on binary code which is “0” and “1” or on/off. It is much easier to translate a digital signal than an analog signal. Some signals are a weak voltage and may also need to be amplified.

Output Drivers

Output drivers are transistors used to control the power or ground (usually ground) to a; injector solenoid, modulator valve solenoid, AC relay, fan solenoid, intake heater relay, starter relay, EGR solenoids, to name just a few things the computer can control. The transistor is like a solid-state relay with no moving parts. Some engine computers have a separate driver module. Since these output devices generate the most heat in the computer, many computers use a finned design or a cooling plate to dissipate the heat.

Maintenance Tip: Output drivers are very sensitive to overcurrent (amperage) and can easily be burned out by someone using a jumper or incorrect testing procedure. If you have a bad fault code for injector driver #5, the injector driver #5 has probably been burned out. Check the resistance of injector #5 solenoid. Low resistance or a short circuit could increase the amperage and damage the injector driver.

Computer System Operation

Computer systems are divided into three areas: input, processing, and output. Input to the computer revolves around sensors and switches. Processing is done inside the computer. Outputs are devices like solenoids, injectors, pressure regulator valves, relays, and indicator lights.

The computer system operates entirely on voltage. Most sensors convert a voltage signal, usually a 5 volt signal, into a voltage between 0 and 5 volts. The voltage is then interpreted as a temperature, pressure, or position by the computer. Some sensors send an analog voltage to the computer, meaning it is a constant or variable voltage and other sensors send a DC digital signal, which is an on/off signal or a high/low signal. When a technician connects a scan tool or computer to the system, it reads temperatures in degrees, pressures in PSI, and positions in percentages. The computer has translated these readings for us. The computer plugs the sensor information along with other information into an algorithm and provides a response on what to do to operate the system.

The computer is a collection of components such as memory, processors, analog-to-digital converters, voltage regulators, printed circuit boards, and transistors pretty much the same as a home computer. Vehicle computers must withstand many more temperature, vibration, and environmental variables. That being said, the computers running the systems on our vehicles are very reliable.

When the computer makes a decision from the information provided, it operates devices such as solenoids, relays, motors, and indicator lights. Many of the output device circuits are controlled from the ground side of the circuit. Since most computer circuits are low amperage circuits, the computer can use a relay to control a higher amperage circuit.

Example: The AC clutch coil is a high amperage (10A) electromagnet. The AC clutch is turned on or off by the computer. The computer controls the ground path of the AC relay coil (pins 85 and 86), which is low amperage (.15A). The magnetism generated by the relay coil closes the NO contact (30 to 87) in the relay and connects the high amperage to the AC coil. This allows the computer to control a high amperage device with a low amperage control circuit.

When the computer detects a problem, it turns on the Malfunction Indicator Lamp or MIL. When this happens, it will store a fault code that the technician can retrieve. A problem in a circuit usually has one of three causes; the computer (very rare), the component (40% or better) and the wiring (40% or better). This means most of the time the problem will be related to components or wiring.

Temperature Sensor

Temperature Sensors

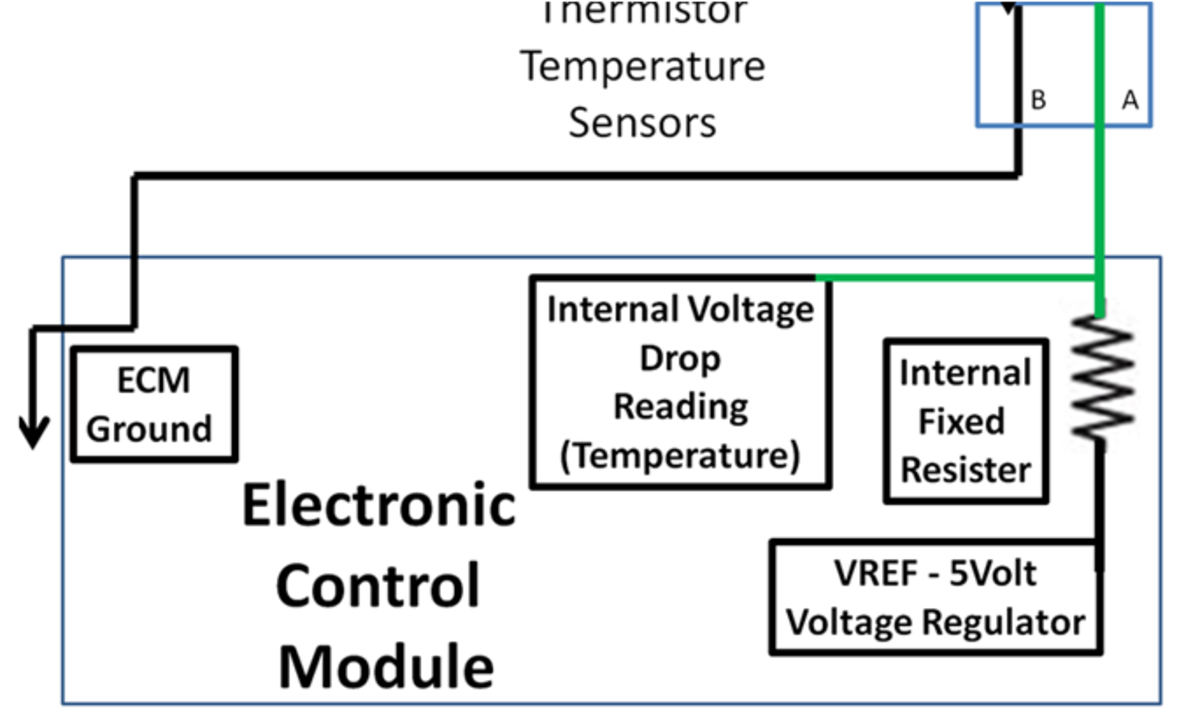

A temperature sensor is also called a thermistor. The resistance inside is sensitive to temperature. When the temperature changes around the resistance, the resistance value changes. There are two types of thermistors used in vehicles; Negative Temperature Coefficient or NTC, which is the most common, and Positive Temperature Coefficient or PTC, rarely used in vehicles.

NTC thermistors increase resistance when the temperature goes down and decrease resistance when the temperature goes up. Resistance and temperature go in opposite directions.

PTC thermistors increase resistance when the temperature goes up and decrease resistance when the temperature goes down. Resistance and temperature go in the same direction.

The computer sends a 5 volt voltage to the sensor and monitors the voltage.

The sensor has two wires: the 5 volt wire and a ground wire.

The sensor has two pins that connect to the sensor resistance.

The circuit must be complete for the sensor to read correctly. If the 5 volts or the ground wire has a problem, the sensor cannot be read correctly. This will usually give a temperature reading of about -36°F. This is a dead giveaway, the sensor circuit has an open circuit.

The sensor must be exposed to the temperature of the air or fluid it is sensing.

NTC thermistors are used for, among other temperature readings:

Engine Coolant Temperature or ECT

Ambient Air Temperature Sensor or AAT

Manifold Air Temperature or MAT

Transmission Oil Temperature or TOT

Engine Axle Temperature

Fuel Temperature or FTS

Potentiometers

The most common potentiometer is the throttle position sensor located on the throttle body or accelerator pedal.

Potentiometers

Potentiometers are position sensors. The most popular potentiometer is the throttle position sensor on the accelerator pedal. In this section, we will use the throttle position sensor (TPS) also called the accelerator pedal position sensor or electronic throttle pedal as an example, as it is the most common.

Note: On many gasoline engines, the TPS is located on the engine’s throttle body. With electronic throttles or electronic diesel engines, the TPS is located on the accelerator pedal.

The TPS uses a three-wire connection.

A 5 volt reference voltage or VREF is sent to the sensor from the computer.

Ground circuit either to chassis ground or ground through the computer.

The signal wire corresponds to the variable voltage between 0 and 5 Volts as the sensor’s wiper arm scrapes across the sensor’s resistance.

The 5 Volt VREF is the sensor’s source voltage. This 5 volts may be shared by other sensors. This means a problem with this circuit can affect multiple sensors.

The ground circuit completes the 5 volt circuit through the resistance to ground. The ground may also be shared with other sensors.

The signal wire is like a voltmeter making a voltage drop across the resistance. At idle or with the pedal in the released position, the voltage is a low voltage reading, typically between 0.5 and 1.0 Volt.

At full throttle or WOT, the voltage is high, between 4.5 and 4.8 Volts.

The TPS will usually set a fault code if the signal wire voltage is 0 or 5 volts. The signal should never reach these extremes.

When the pedal is pressed, the voltage increases from the minimum of about 0.5 volt to about 4.8 volts. Early TPS sensors were adjustable and, later, TPS sensors, the computer “learned” the minimum and maximum voltages. Through a scan tool or PC, this is usually a throttle position from 0% to 100%.

Pressure Sensors

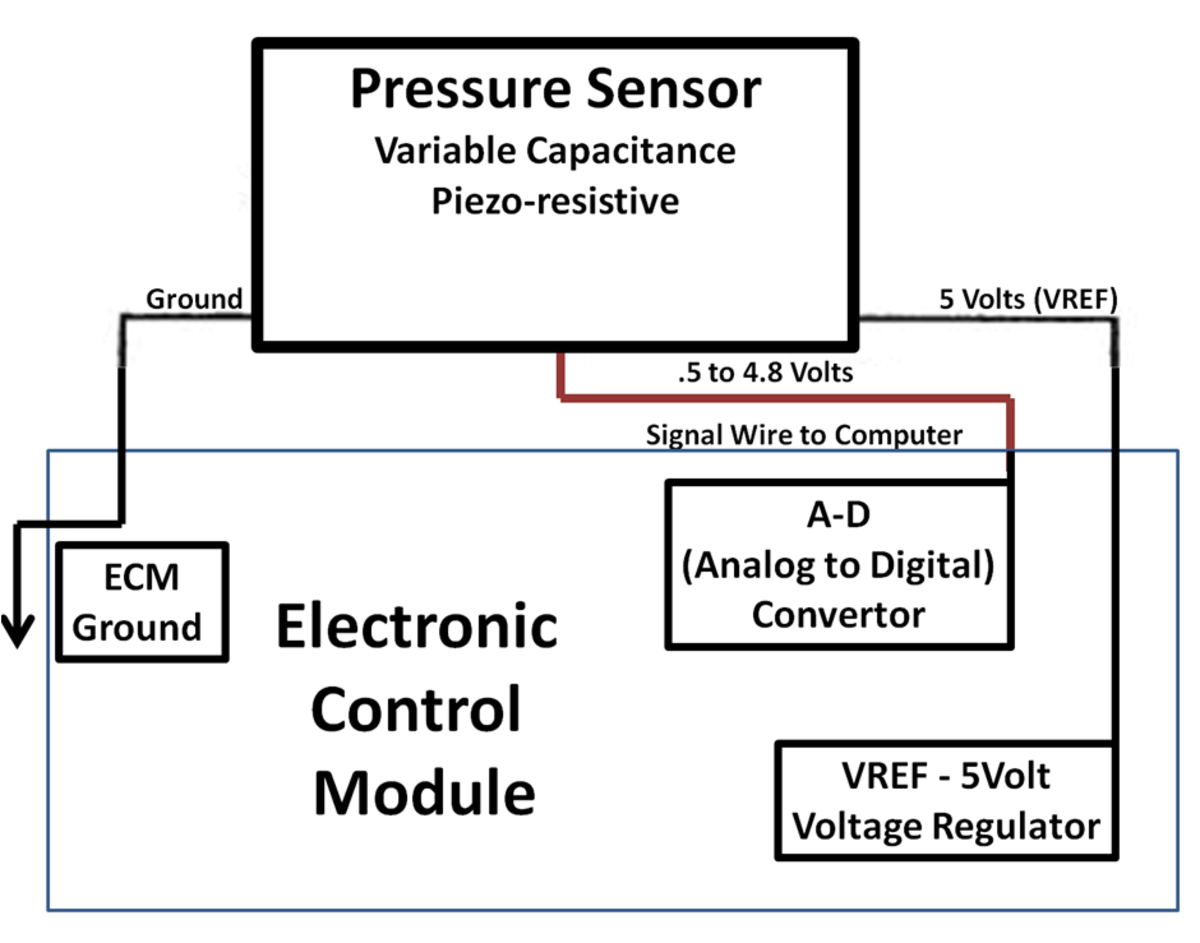

Pressure sensors are called variable capacitance or piezoresistive sensors. They are used to measure various pressures on vehicles. Some of the pressures this type of sensor can measure are; atmospheric pressure (BARO or barometric pressure), intake manifold pressure or vacuum, manifold absolute pressure (MAP) or boost pressure (BPS), oil pressures (OPS), fuel pressures, air conditioning system pressures, and transmission oil pressure.

[B] Pressure Sensor Wiring

Pressure sensors are three-wire sensors set up similarly to the TPS.

A pressure sensor uses a three-wire connection.

A 5 volt reference voltage or VREF is sent to the sensor from the computer.

Ground circuit either to chassis ground or ground through the computer.

The signal wire is the variable voltage between 0 and 5 volts as the pressure changes the resistance across the sensor and its signal voltage.

The 5 Volt VREF is the sensor’s source voltage. This 5 volts may be shared by other sensors. This means a problem with this circuit can affect multiple sensors.

The ground circuit completes the 5 volt circuit through the resistance to ground. The ground may also be shared with other sensors.

The signal wire will send a signal to the computer between 0.5 and 4.8 Volts depending on the pressure it has detected.

Two types of pressure sensors are the most popular:

A variable capacitance sensor uses a ceramic disc that, when pressure is applied, moves closer to or further away from a steel disc. This changes the capacitance value and changes the signal voltage to the computer.

A piezoresistive type sensor is also called a Wheatstone bridge. It uses a silicon chip that flexes and changes its resistance value to change the signal sent back to the computer.

The computer changes this voltage signal into a pressure reading.

Permanent Magnet Sensors

Speed and Position Sensors

There are many areas of the vehicle where rotational speed needs to be measured. On electronic engines, engine speed and position are important for fuel injection timing. Some of the speed sensors are:

wheel speed (WSS),

vehicle speed (VSS),

transmission input speed (TIS),

transmission output speed (TOS),

crankshaft speed and position (CKT)

and camshaft speed and position (CMP).

Two types of speed and position sensors used in today’s vehicles; the permanent magnet generator and the Hall effect sensor. The permanent magnet generator or induction pulse generator is widely used for vehicle speed sensors, wheel speed sensors, transmission speed sensors, and crankshaft speed sensors. The Hall effect sensor is used as a precise speed and position sensor for crankshaft and camshaft position and speed.

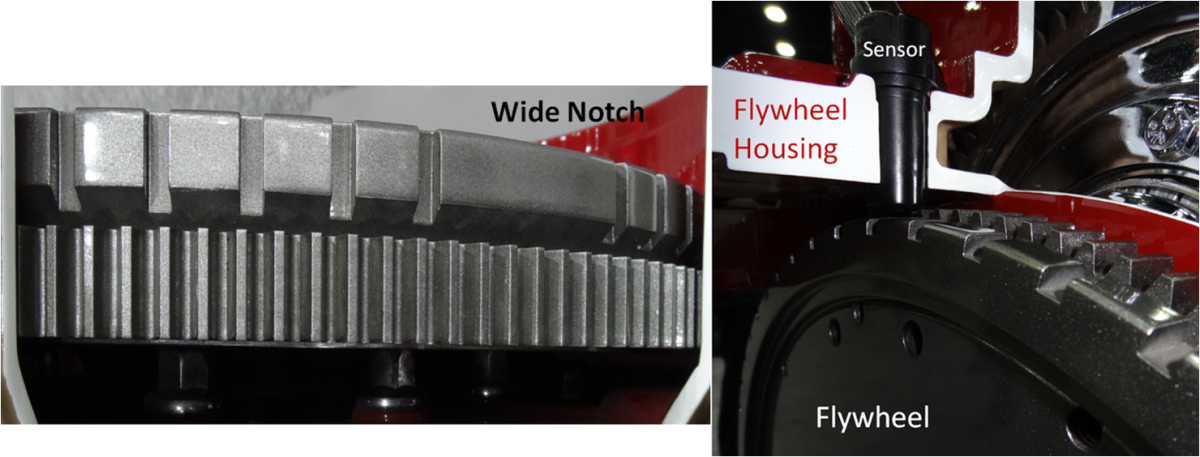

Permanent Magnet Generator Operation

Permanent magnet generators use a permanent magnet surrounded by a thin coil of wire. A tone ring or reluctor wheel has a raised edge followed by a low gap. The magnet is very close to the ring. As the ring rotates past the magnet, the raised edge creates a magnetic field around the magnet. As the ring continues to rotate, the low gap comes by the magnet. This weakens the magnetic field and it collapses through the wire coil, generating a weak alternating current. As the ring speeds up, the pulses become stronger, more frequent, and produce more current. For most applications, the high and low gaps are evenly spaced around the ring. If the sensor is used for engine speed and position, an odd notch will identify that position to the computer by varying the signal whenever the odd notch passes the sensor. The gap between the sensor and the ring is critical. Too much gap and the signal will be